Sosi casting or water glass (lost wax sosi)

The Lost Wax sosi process, also known as sosi casting or water glass, is one of the most popular methods used by Castmetal Advanced Services to produce high quality castings.

02/06/2023

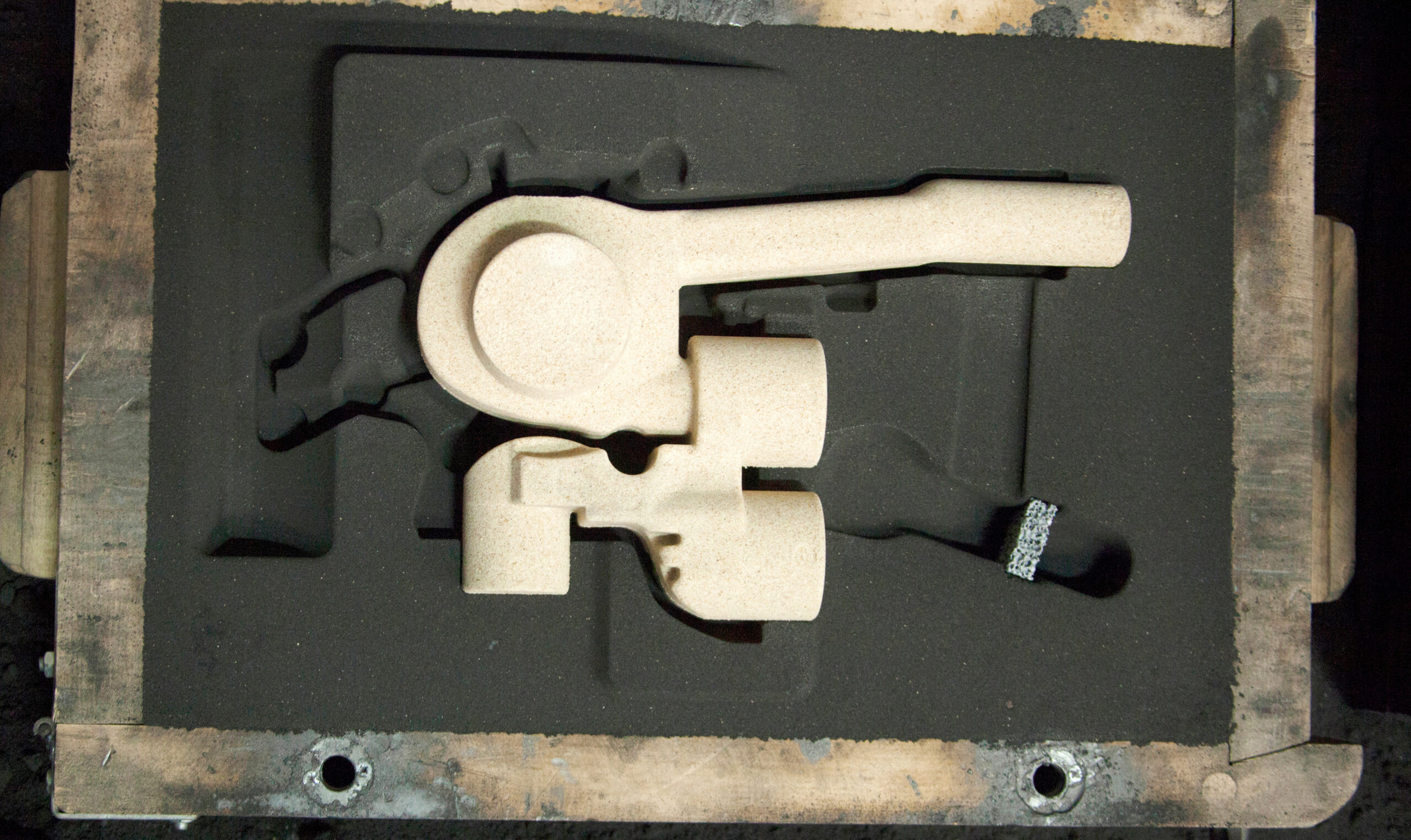

Resin Sand Casting is one of the processes used by Castmetal Advanced Services to produce high quality parts for its customers. This technique is often used because it can produce intricately shaped parts with a high degree of precision and an excellent finish. It is an advanced technique that combines the advantages of traditional sand casting with the use of special resins to improve mould properties and produce complex finished parts with excellent dimensional accuracy. In this article, we take a detailed look at Resin Sand Casting and its benefits in the production of high-quality parts.

The Resin Sand Casting process involves creating a mould from sand impregnated with epoxy resin. This resin is used to bind the grains of sand together, creating a strong, heat-resistant mould. This mould is then used to produce the part by pouring molten metal into it.

The Resin Sand Casting process is used to produce a variety of parts in many sectors, including aerospace, the automotive industry, agriculture, food and pharmaceuticals. This technique is particularly suitable for the production of parts requiring a high level of precision and finish. It can be used to produce parts of all sizes, from the smallest to the largest.

The Lost Wax sosi process, also known as sosi casting or water glass, is one of the most popular methods used by Castmetal Advanced Services to produce high quality castings.

02/06/2023

The "Lost Wax (Investment Casting or Colloidal Technology)" casting process is a method of producing high-precision parts, renowned for its exceptional characteristics.

14/06/2023

Castmetal Advanced Services uses various processes to produce high-quality metal parts, including the Lost Foam process.

29/05/2023