Resin Sand Casting

Resin Sand Casting is one of the processes used by Castmetal Advanced Services to produce high quality parts for its customers.

01/05/2023

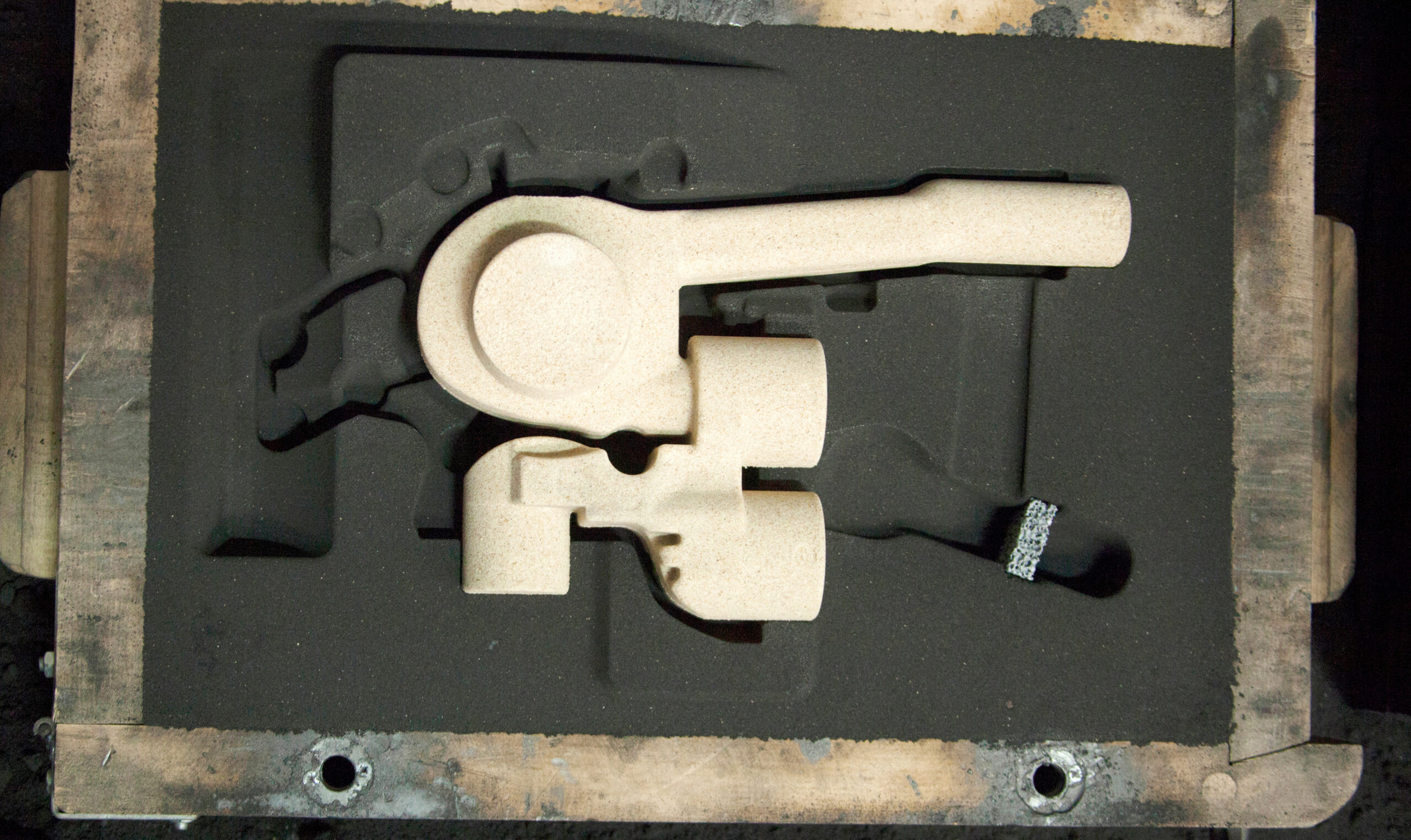

Shell moulding, also known as shell casting, is a production method used in foundries to manufacture metal parts. The technique combines aspects of traditional sand casting and hot casting to produce high-quality, high-precision parts. This advanced technique allows us to produce intricately shaped parts with exceptional dimensional accuracy and a high quality finish. In this article, we shall examine the Shell moulding process and its many advantages.

The first stage of the Shell moulding process involves creating a model of the part to be manufactured. This model is made of metal. The model is used to form a strong shell of rigid sand.

Several mould parts are assembled to form the complete rigid mould. This cavity is then filled with molten metal, such as aluminium, bronze or steel, which is poured into the shell by gravity or pressure.

Shell Moulding is an advanced metallurgical production technique offering major advantages in terms of complexity of shape, mechanical strength and surface quality. At Castmetal Advanced Services, we have adopted this method to meet the specific needs of our customers by producing high-quality bespoke parts. Shell moulding offers reliable, durable solutions for a wide range of industrial applications in the aerospace, automotive and energy sectors.

Resin Sand Casting is one of the processes used by Castmetal Advanced Services to produce high quality parts for its customers.

01/05/2023Silicone casting is one of the most efficient moulding techniques used in the metal casting industry.

23/06/2023

The "Lost Wax (Investment Casting or Colloidal Technology)" casting process is a method of producing high-precision parts, renowned for its exceptional characteristics.

14/06/2023