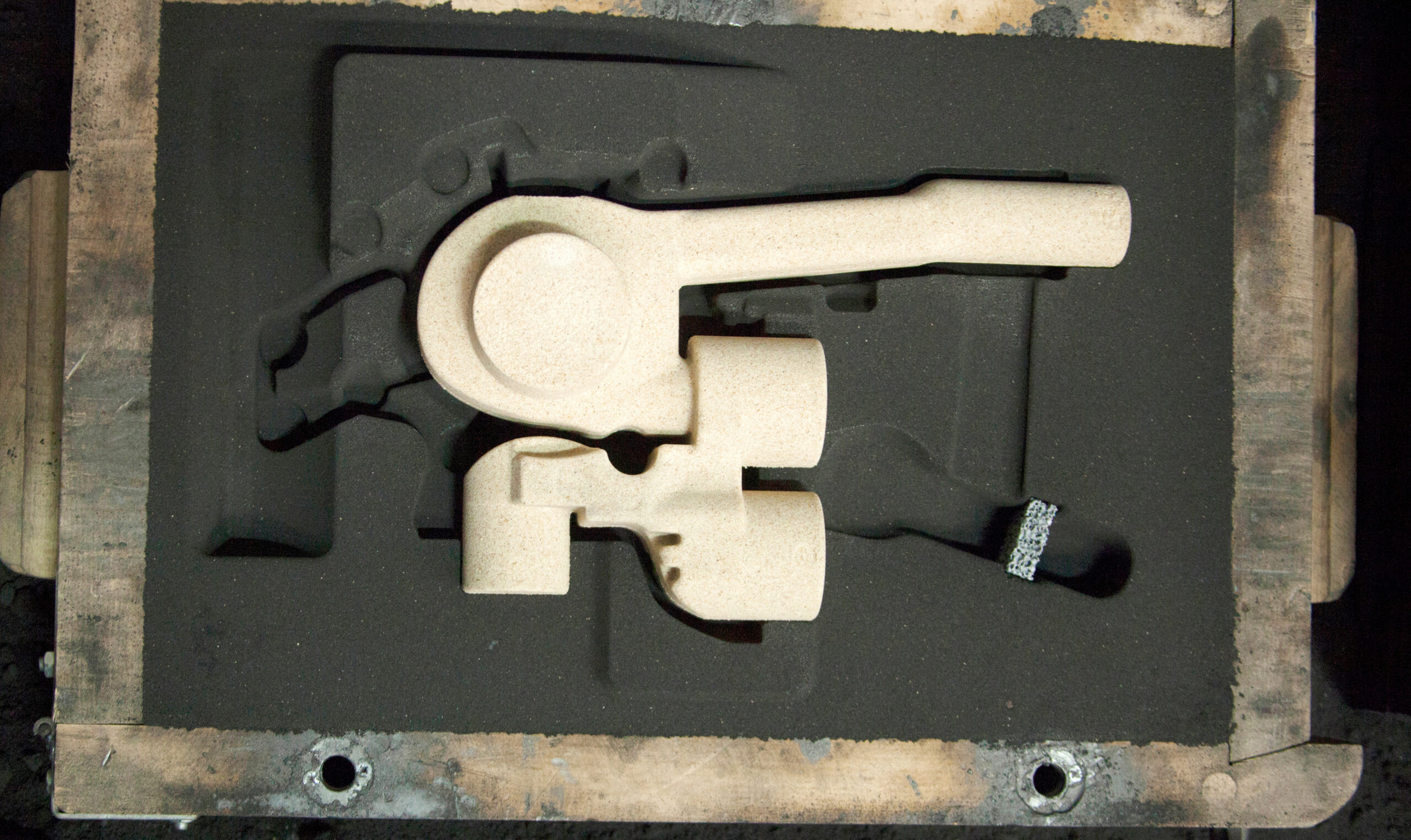

Resin Sand Casting

Resin Sand Casting is one of the processes used by Castmetal Advanced Services to produce high quality parts for its customers.

01/05/2023

Forging is a technique used to produce metal parts by hot forming. This method is used to produce intricately shaped parts with exceptional mechanical properties. At Castmetal Advanced Services, we use the forging process to produce high quality customized parts. The main characteristics of finished forged parts include strength and durability, as well as enhanced metallurgical structure that provides a better mechanical performance.

Forging is used to produce parts from steel, aluminium, titanium and specific alloys. This technique involves heating the metal to a specific temperature, then deforming it under pressure to give it the desired shape.

Forging has many advantages:

At Castmetal Advanced Services, we use hot forging presses to produce parts made of steel, aluminium and specific alloys. We have complete mastery of the various stages in the forging process, from the design of the part to the finish of the surface.

As a means of producing metal parts, forging offers numerous advantages. At Castmetal Advanced Services, we use the forging process to produce high-quality, customised parts tailored to our customers’ specific needs.

Resin Sand Casting is one of the processes used by Castmetal Advanced Services to produce high quality parts for its customers.

01/05/2023

Shell moulding, also known as shell casting, is a production method used in foundries to manufacture metal parts.

10/05/2023

Castmetal Advanced Services uses various processes to produce high-quality metal parts, including the Lost Foam process.

29/05/2023